Introduction

Modbus RTU and TCP are, when compared to PROFINET, PROFIBUS and EtherNet/IP, slow protocols. Therefore, it is not suited for ‘real-time’ control in most cases. However, if the process is also very slow, then Modbus can be fast enough. If things change in seconds, minutes, or hours, then Modbus is fast enough to control it. If things change in milliseconds, then Modbus will not work so well.

The reason for using Modbus for these slow applications is cost. Modbus components are more cost effective.

I have seen Modbus used successfully in two areas: small applications where the equipment is controlled by a person and water applications where either pumps or gates are controlled.

Application Example 1: Human Control of a Punch Press

This application traditionally uses a series of buttons and relays. The operator presses this button to lower this part and this other button to move this other part. All the interlocks would be hardwired.

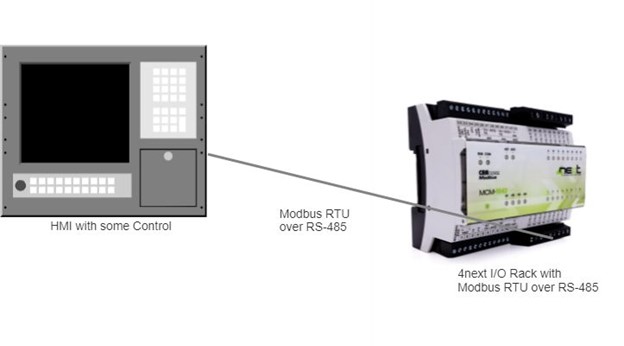

Now, we can use a combination of an HMI and Controller and Modbus to talk to the IO. There are low-cost touch-panel displays that can easily handle this simple software and light control. I call it light control, because the program is not ‘controlling’ anything, it is just preventing the user from doing a combination of tasks that would break something. Having the interlocks programmed has the added benefit that you can build in diagnostics so the user can see what interlock is being tripped.

Using Modbus down to the IO lets you use cost-effective equipment. The equipment does not need to be as powerful as it would if it had to support PROFIBUS, PROFINET or EtherNet/IP because of the reduced timing requirements.

Every element of using this equipment is going to be low-cost and easy to use.

Application Example 2: Control of water levels

This application I have seen many times in various forms, all using Modbus. In the one that I will talk about today, the end user had to control the water level in different irrigation canals. Like the first application, the control was done by people. There were no interlocks, but the raising and lowering of the control gates had to be pulsed. Also, the operator had to see what the various levels were.

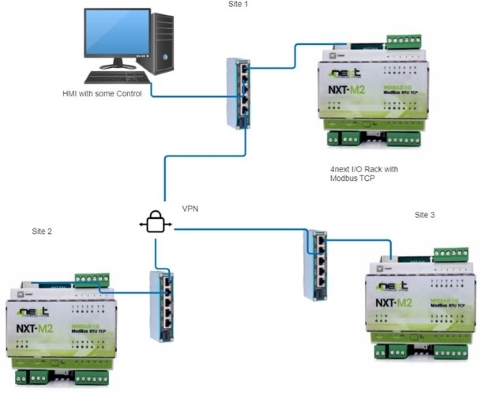

At one of the three sites, they had a computer that operators could use when they were on site. We loaded Codesys software on it and created a program to communicate with 4next IO modules via Modbus TCP and to provide the pulses. Codesys also had a built in HMI for the operator to use.

The three sites were all on the same Local Area Network tied together via VPN tunnels. The Codesys application could easily handle all three sites. Operators could tunnel into the computer running the app from anywhere on the company intranet. The equipment and software costs for this were a fraction of the cost of the traditional PLC and HMI approach.

This was a cool little application. It was completed using hardware and software that cost a fraction of what I was used to using. Most of all, it worked!

Conclusion

There is a certain type of project that Modbus just excels at. Controlling slow processes is certainly one of them.

If you have a slow process that you need to control, give us a call at 705-868-8745 or email us at admin@jcomautomation.ca, and we can discuss your application in detail.